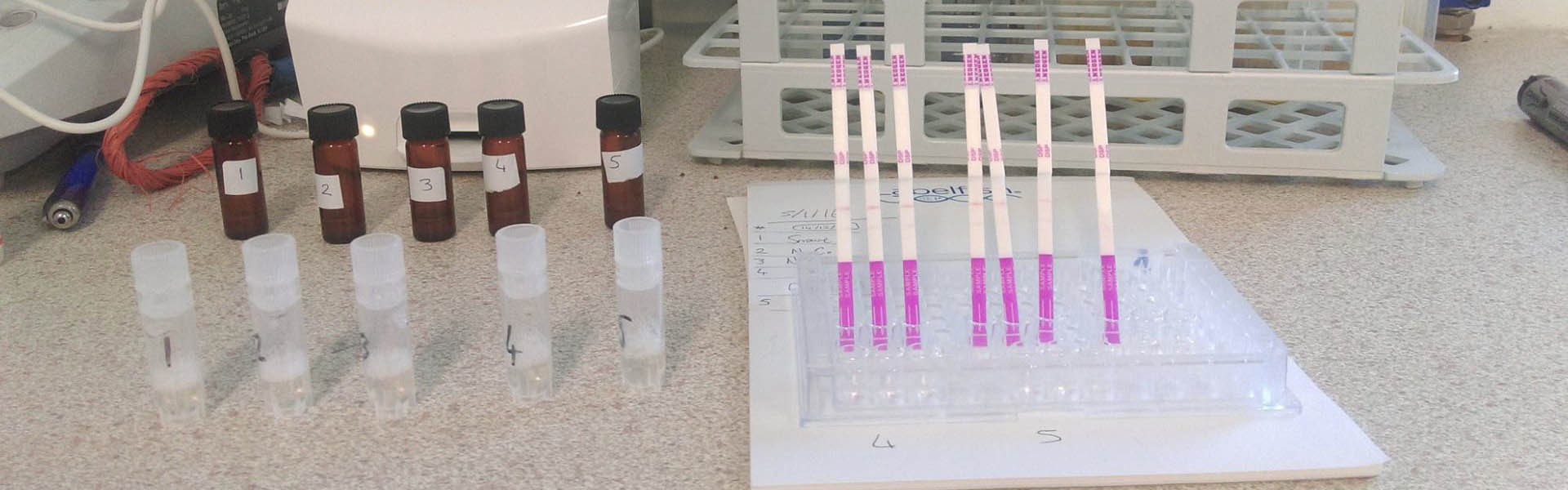

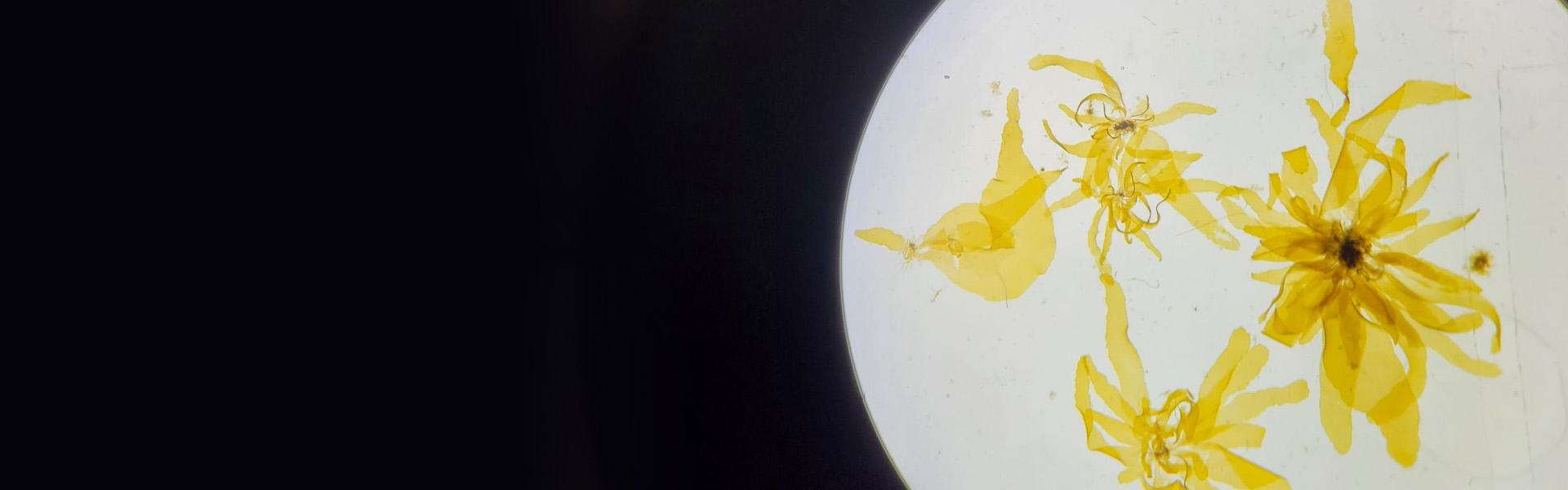

EU is the largest biodegradable polymers consuming region. Major market drivers for biodegradable polymers include legislation, depleting landfill capacity, pressure from retailers, growing consumer interest in sustainable plastic solutions, a quest for fossil oil and gas independence and the reduction of greenhouse gas emissions. The production of polylactic acid (PLA), a biodegradable and bioactive thermoplastic, and other biopolymers is now based in natural resources like corn, wheat, sugar beets and sugar cane. There is an increasing concern that the use of those raw materials will compete with food, feed or energy production, with consequent escalation of raw material costs and negative environmental effects. SeaBioPlas proposed seaweeds: offering advantages over traditional feedstocks, including higher productivities, no competition for land use, minimal water consumption while having similar sugar contents and contributing to the reduction of CO2 emissions. SeaBioPlas included a complete integrated solution to the plastic SMEs stakeholders through the scientific knowledge provided by the RTDs, from the production of the feedstock in sustainable Integrated Multi Trophic Aquaculture systems, to the development of the biopolymers using innovative technologies of reduced environmental impact until the validation test of the seaweed-based polymers in greener plastic products (shrinkable and stretchable films, adhesives, plastic additives and coatings). As a complement, the viability of valorizing the seaweed residues as ingredients for animal feeds was assayed in dairy farms and IMTA sites.

SeaBioPlas – Seaweeds from sustainable aquaculture as feedstock for biodegradable bioplastics

| Duration | 2013 - 2015 |

|---|---|

| Funding Body | European Commission FP7 SME Programme |

| Project Costs | €1,490,000 |

| Project Co-ordinator | Bantry Marine Research Station (then Daithi O’Murchu Marine Research Station) |

| Number of Partners | 11 |

| Website | EC Report Summary |